Core Technological Competence of EQCELL

| Automation | Plasma | Vacuum Process |

EQCELL is proactive in entering new businesses by developing technologies needed for diverse equipment industries based on our core manufacturing technologies.

Our Business Areas

Large size OLED

- Large-sized panel transportation system

- Substitution and refinement of vacuum nitrogen CDA

Secondary battery

- Secondary battery packaging

- In-line automation equipment

Smart device

- EMI shielding technology

- Precise alignment attachment

Flexible display

- Plasma low-temperature deposition

- Transparent conducting thin film process

Semiconductor

- Etching, Cleaning, Treatment

- Semiconductor process diagnosis system

Solar cell

- Solar cell parts business

Core Technologies

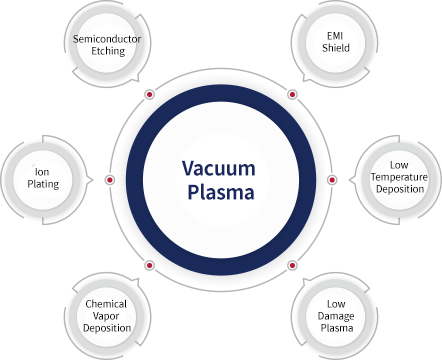

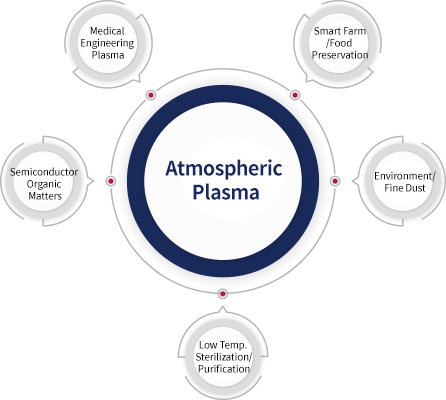

Plasma Technology

Plasma Technology

We secure new growth engines by focusing on R &D of vacuum & atmospheric plasma technologies

Definition

- Innovative convergence and integration technology that uses plasma a state of matter in which electron and iron are equally existing for various businesses semiconductor display energy bio medicals beauty machinery construction and advanced agriculture

Key Features

- Plasma Low-Temperature Process

-

Creating high-quality conductive thin film under 100℃

(Low resistance + high light transmission) - World’s first mass production (2014)

-

- Plasma Room/High Temperature Process

- Creating high-quality conductive thin film that is responsive to customer needs

- In-line sputter & PECVD with high-speed deposition capacity and high productivity

- High-efficiency cylindrical target and optimized gas head

-

- Plasma Treatment Process

- Surface treatment of diverse substances and products

- Etching, Annealing, Cleaning, Treatment

-

Electromagnetic Shield Technology

Electromagnetic Shield Technology

Definition

- Technology to shield EMI by creating coating film on the surface of semiconductor device within smart products

Key Features

- EMI Shield In-line Sputter

- Satisfying the condition of thinning the EMI shielding thickness

- Realizing the process environment under 100℃ aimed at protecting devices

- Superior deposition rate and high productivity of high-quality coating film

- Cylindrical type cathode, compact structure

-

Gas Purification Technology

Gas Purification Technology

Definition

- Technology to create optimal vacuum/CDA/N2 treatment environment with the aim of protecting pollution from atmospheric gases moisture and particles

Key Features

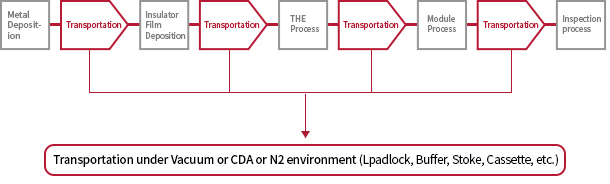

- Vacuum/CDA/N2 Transportation System for OLED Line

- Mass production of the 8th generation large-sized transportation technology under vacuum/CDA/N2 environment

-

- Adopting gas control sealing particle reduction and high-density loading technologies

-

Gas Substitution/Refinement

Gas Substitution/Refinement

Moisture Elimination

Moisture Elimination

Particle Elimination

Particle Elimination

High-density Loading

High-density Loading

Automation System Technology

Automation System Technology

Definition

- Technology to build a system where entire process ranging from product supply to manufacturing transfer inspection classification storage and packaging is automatically operating

Key Features

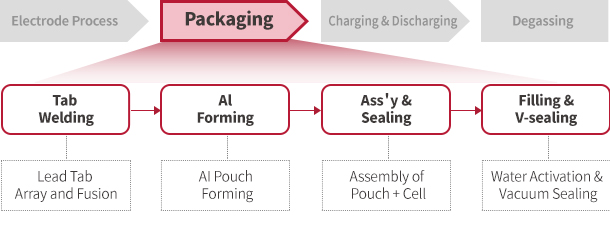

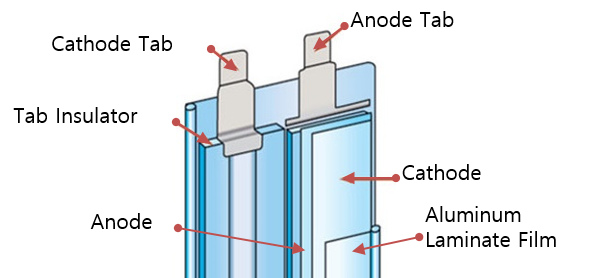

- Battery packaging automation equipment for the secondary battery manufacturing process

- Secondary battery packaging automation process

- Pouch-typed secondary battery structure

-

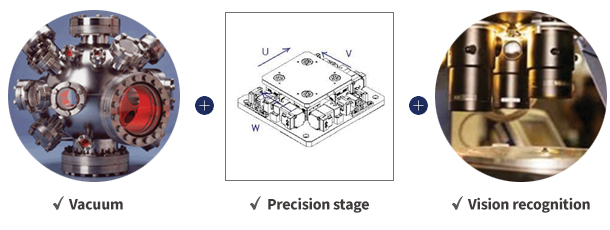

Precise Alignment Technology in Vacuum

Precise Alignment Technology in Vacuum

Definition

- Technology applicable to the next-generation premium display manufacturing process which is converged by vacuum technology and precise alignment technology

Key Features

- Vacuum assembly chamber

- Precise assembly process under vacuum environment

- Curved panel assembly technology available for the next-generation display

- Minimizing error range absorption & adhesion type ⇒ high durability flatness and design

-

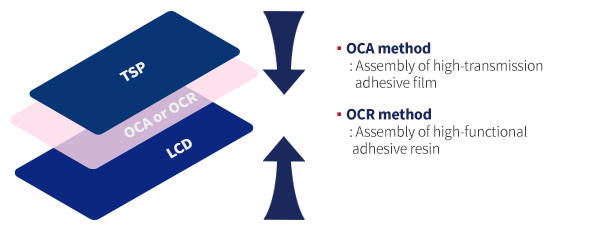

- Display assembly method

-